Beer wouldn’t be possible without yeast, and no one knows that better than our very own Microbiologist, Wade Begrow. Not many are aware of the integral role yeast plays in the beer we brew (and drink) so, in the name of education, we sat Wade down and asked him some burning, yeast-related questions.

What is yeast?

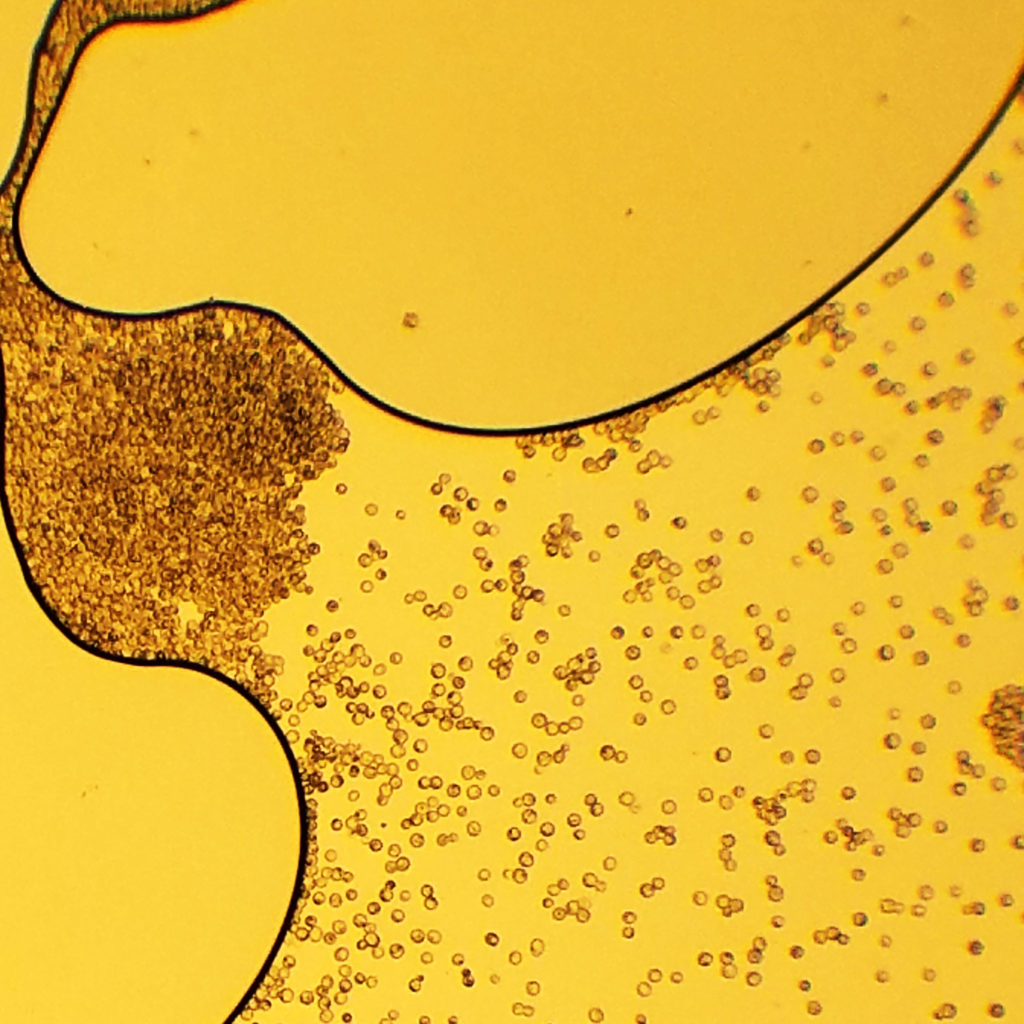

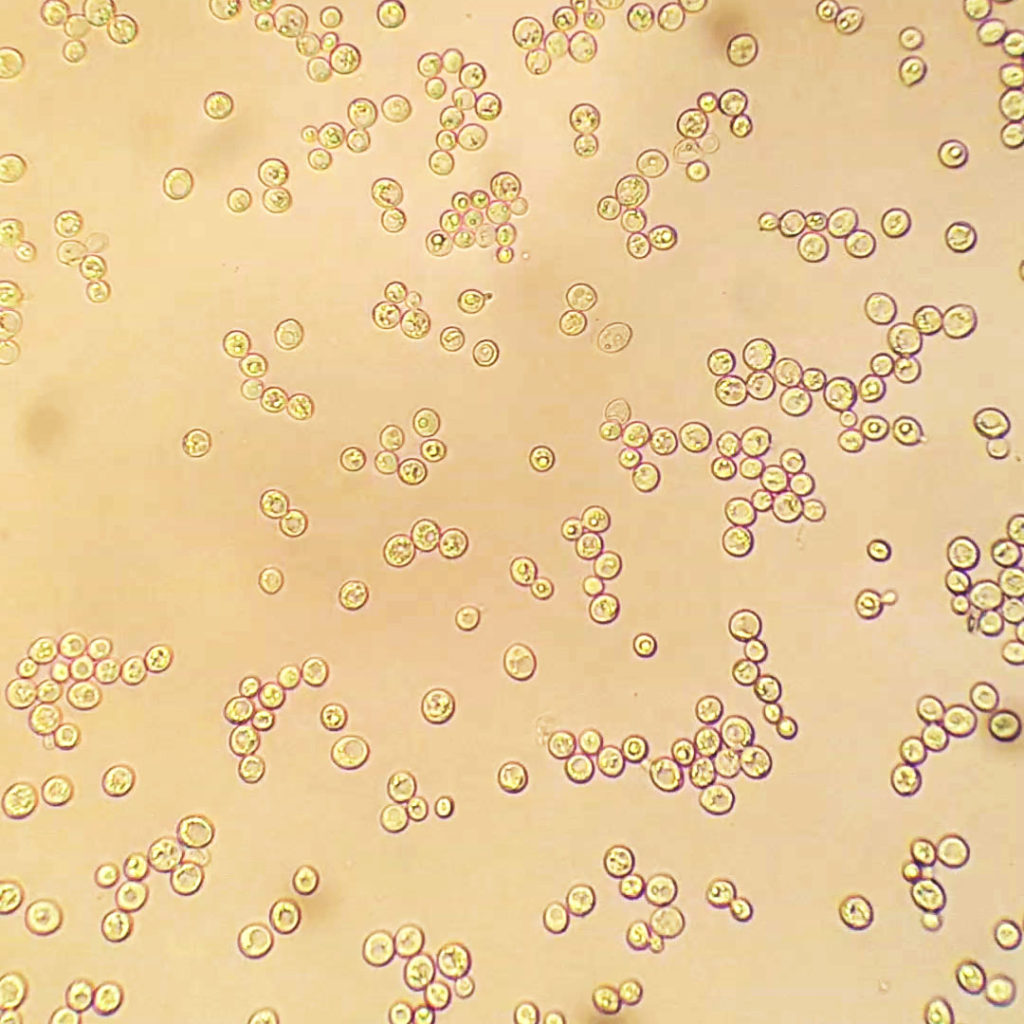

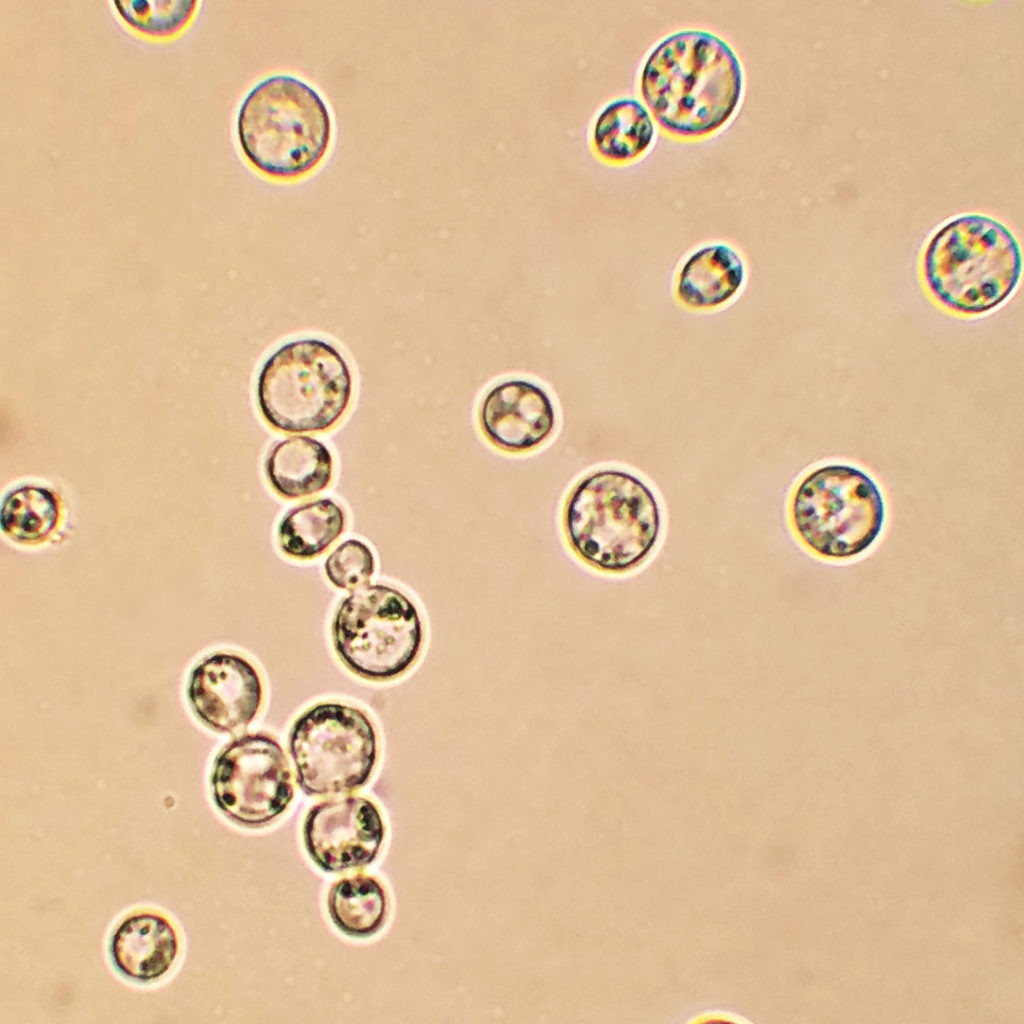

By definition, yeast (singular and plural) are unicellular eukaryotic fungal organisms. Humans are eukaryotes too, so our genes are more related to yeast than bacteria! Yeast are microbes, meaning that individual cells cannot be discerned with the naked eye. A microscope is needed to look at individual cells.

What role does yeast play in beer?

In brewing, two strains of yeast are primarily used: Saccharomyces cerevisiae and Saccharomyces pastorianus. Saccharomyces cerevisiae or “sugar fungus from beer” is used to produce ales (everything from All Day IPA to Breakfast Stout). Saccharomyces cerevisiae is also used for baking and bioethanol production. Saccharomyces pastorianus is used for our lager beers. It’s similar to our ale yeast, but produces different flavors and works at a lower temperature.

Saccharomyces cerevisiae and Saccharomyces pastorianus are essential to the brewing process because they are capable of converting sugars to ethanol (drinking alcohol) and carbon dioxide. This is called alcoholic fermentation and it is critical to making beer (or any type of alcoholic drink). Without yeast, we would be stuck with non-alcoholic hoppy sugar water. Every batch from the brewhouse is inoculated with literally trillions of yeast cells to make beer. For reference, that’s more cells that there are stars in the Milky Way. Far out!

Why is your job important in a brewery?

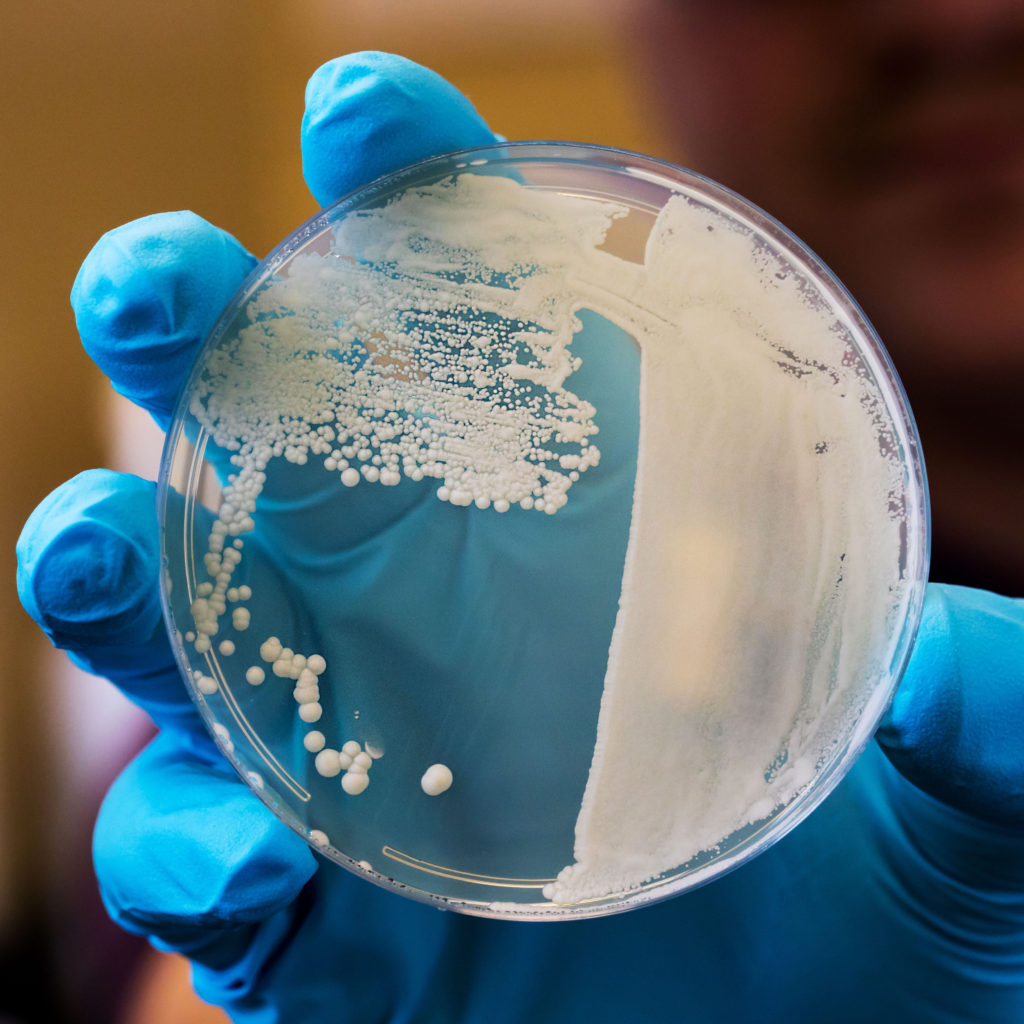

I work very closely with the Yeast Management team at Founders to provide the brewery with pure, contaminant-free yeast cultures on a routine basis. The Yeast and Cellar team do an outstanding job and beer production simply wouldn’t be possible without them. Breweries that do not produce their own yeast in-house must purchase it from yeast suppliers, which can be problematic. Some of the problems include:

- not receiving the right yeast

- receiving contaminated yeast

- not receiving yeast on time

- receiving poor quality yeast

Brewing yeast aren’t the only microbes in the brewery and we carefully screen every batch for microbiological contamination. After all, contamination can affect the quality of our beer. There are wild yeast and bacteria that live in our brewery and they can be detrimental to our beer. A sound microbiological testing program is a major part of producing consistent world-class beer. We test every batch numerous times for microbiological contamination.

What is one of the biggest challenges of managing a yeast program?

I’m a big fan of our lager beers like Solid Gold, but it can be challenging to juggle two different yeast strains at once. We take the utmost care to keep ale yeast segregated from lager yeast, but it can cause extra headaches for our beer scheduling team to keep them separate. It would be much easier if we had isolated facilities for ales and lagers, but we are up for the challenge of doing both in the same facility!

TL;DR: No yeast = no beer (or leavened bread, bioethanol, wine, spirits, etc.)